When it comes to manufacturing leather bags, choosing the right manufacturer is crucial for the success of your business. Usually, the best manufacturing options lie overseas, like in Asia and Indian subcontinent. Often difference in time zones, language barriers, and culture are overlooked. And cost reduction is prioritized. Though manufacturing leather bag from overseas can be a highly rewarding. Sometimes depending on nature and state of your business manufacturing leather bags overseas can end up being a total loss.

This article will cover the top 8 things that you need to consider before you decide manufacturing leather bags from overseas. Whether you\’re a seasoned entrepreneur, sourcing manager or a new business owner. It is important that you know these things before you dive into global sourcing.

Communication

One of the biggest challenge you\’ll face is communicating with oversea manufacturer. Language barriers and cultural differences can make it difficult to effectively communicate your requirements to your overseas manufacturer. When a manufacturer is quoting low price. It is possible that they lack proper expertise, technology or education of communication. Misunderstandings can lead to mistakes in the design, quality, and even the overall timeline of your products.

For instance, if your manufacturer doesn’t fully understand your design requirements. They may end up producing bags that don\’t meet your expectations. Or, if there are cultural differences in business practices. Such as different expectations for punctuality or negotiation tactics. It can also create confusion and misunderstandings.

Overcome these challenges by establishing clear and effective communication procedure from the start. This may include hiring a translator. Using clear and concise language in your communications. Seeking & offering clarifications whenever required. And establishing a mutual understanding of business practices and expectations. You should also consider visiting your manufacturer in person, if possible. This will help build relationship and ensure clear communication. By investing time and effort into effective communication, you can minimize misunderstandings. And thus ensure a successful manufacturing process.

Design of Bags

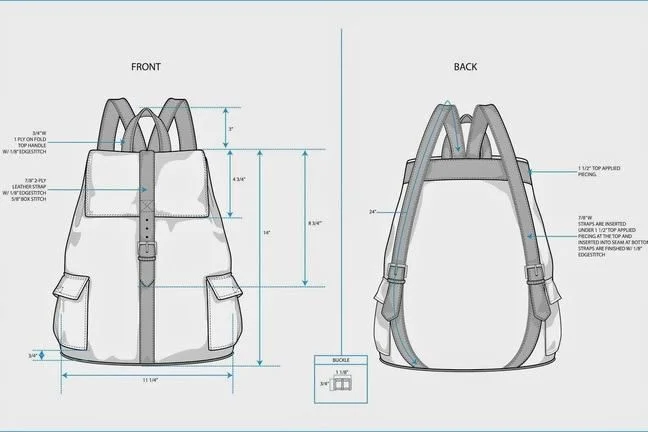

Having a clear and detailed tech pack is very important. A tech pack serves as a blueprint for your manufacturer. Detailing every aspect of your bag\’s design. Which includes measurements, type of leather, color, hardware, and other specifications.

However, we understand that not every client may have a complete tech pack available. In such cases, a simple sketch with measurements can also be workable. As long as it provides your manufacturer with a clear idea of what you\’re looking for. You can also work with your manufacturer to make modifications to your design throughout the manufacturing process, as needed.

It’s important to note that having a clear design and functionality in mind is crucial. Thus, you can ensure a successful manufacturing process and a high-quality final product. Clarify factors such as the size, shape, closure type, extra pockets, etc.

By providing sufficient details, you can minimize the risk of misunderstandings. And ensure that the final product meets your expectations. Taking the time to consider the design and functionality of your bag can also help to ensure a successful manufacturing process. And thus, a high-quality final product.

Quality of Leather

It\’s important to keep in mind that quality can be a subjective term, and not all manufacturers may prioritize the same aspects of quality as you do. It\’s important to communicate your expectations clearly when it comes to the quality of the leather used in your bags.

When selecting a manufacturer, it\’s helpful to look for one that has experience working with high-quality leathers. So that they can source materials that meet your standards. Work with a manufacturer who shares your commitment to quality. This will help to ensure that your leather bags are made with the finest materials available.

It’s also important to consider your own expertise in leather when selecting a manufacturer. If you\’re not an expert in the field, it can be helpful to educate yourself on the different grades of leather. And what to look for in terms of texture, durability, stiffness etc.

The quality of the leather used in your bag will impact its total value and appeal. By knowing your leather better. You can ensure that your leather bags meet the desired standards of your market.

Sampling of Bag

Sampling is a crucial step in the manufacturing process for leather bags. And it\’s important to approach it with attention to detail. Clear communication with your overseas manufacturer is the key. The sampling process allows you to test the design and functionality of the leather bag. Make any necessary adjustments before mass production begins.

Inform your manufacturer your launching deadline. This will help you receive your samples on time. And make any necessary changes before production begins. Sampling process may take 2-4 weeks to complete. And if you are not comfortable giving corrections online. And want to give correction after seeing the sample physically (wise decision though). Then you also need to consider the back-and-forth shipping time of the samples. Not to mention the time-consuming payment process if you are completely new to this. Once you receive sample, pay close attention to the quality of the sample. Check for stitching, hardware, and overall construction. Provide detailed feedback to the manufacturer.

In case you do not have a clear and complete tech pack. The sampling process can be time-consuming and may need several rounds of iterations. In such cases, patience is key. Providing detailed feedback on each sample is essential. The communication and feedback you provide will impact the final product. So, take the time to review and approve each sample.

Note that sampling is a time and resource involved process for the manufacturer hence you will be charged for. And the sampling charges are in general exclusive of sample shipping charges. For large quantity of orders. These sampling charges are paid back later on, adjusting with final payment.

The sampling process is an opportunity to experiment with different materials and finishes. And create a unique and appealing final product that stands out in the market. By working closely with your manufacturer. And paying close attention to the details. You can ensure that your leather bags meet your design and quality standards.

Hardware Sourcing

Another essential aspects to consider is hardware sourcing. Hardware includes all the metal parts that are used in the bags, such as buckles, zippers, and rivets. The quality of hardware can impact the overall look and durability of the bag. So, it\’s essential to pay close attention to this aspect.

When working with an overseas manufacturer. It\’s important to ensure that they have access to high-quality hardware suppliers. However, if you\’re looking for custom hardware or small quantity orders, it\’s recommended that you have hardware sources of your own. As most of the manufacturers won’t be willing to source hardware in small quantity. Also having your own hardware manufacturer. Will give you more control over the design and quality of the hardware. As well as ensure that it matches your brand\’s aesthetic. Nonetheless if you want to save the trouble. You can always use hardware available in stock of the manufacturer. This will simplify the whole process.

Another important factor to consider when sourcing hardware is its sustainability. If your consumers are more conscious of the environmental impact of fashion. It\’s important to ensure that the hardware used in your bags is environment friendly. This can include using recycled or upcycled hardware. Or opting for hardware made from sustainable materials.

Overall, hardware sourcing is a crucial part of manufacturing leather bags. Having manufacturing source or your own can help you maintain your uniqueness. If you are targeting a luxury market for your brand. Although same can be achieved by having a good relationship with your manufacturer.

Cumulative Cost

One of the biggest mistakes you might do when considering manufacturing leather bags overseas. Is not considering the peripheral costs along with cost of manufacturing. Many jumps into conclusion when seeing the low cost of product manufacturing. While the cost of manufacturing may be lower in other countries. It\’s important to remember that there may be additional costs involved that you may not have accounted for.

For example, shipping costs, duties, taxes, transportation costs can all add up quickly and significantly impact your overall cost. These costs can vary depending on the country you\’re importing from and the country you\’re importing in. It\’s important to research and understand all the associated costs. And include them into your budget. Make sure you have a clear understanding of all the costs involved before making any decisions.

It is also important to consider the potential risks involved with manufacturing overseas. While the cost may be lower, there may be risks such as longer lead times and quality control issues.

When it comes to the cumulative cost of manufacturing leather bags overseas. It is important to weigh the benefits against the potential risks and costs involved. By doing your research and being realistic about your budget and expectations. You can make an informed decision whether to manufacture locally or overseas.

Shipping and Logistics

The reason why this is even a point is because currently (2023) shipping charges are skyrocketing due to oil price hikes. Shipping and logistics are a critical aspect of overseas manufacturing for leather bags. While the manufacturing cost may be low. It is essential to consider the shipping costs and logistics involved. To get the finished product in your hand. This can significantly impact the total cost of manufacturing. And can lead to unexpected expenses.

Another consideration is the process of releasing the shipment from customs. This can be a complex and time-consuming process, especially if there are any issues with documentation or compliance. Consider the overall logistics of shipping of both the samples and the finished product. Including factors such as the mode of transportation, transit times, and any storage or handling requirements. It\’s important to work with a shipping company that has experience navigating customs regulations. And can help to ensure quick and efficient release of your shipment.

Although to avoid all these complex processes. You can work with a shipping company that can provide end-to-end logistics support. And can help to ensure that your finished product is delivered on time and in good condition. Also, to avoid hassles you can always work with the shipping channel of the manufacturer. All manufacturers have their own shipping and logistic channels.

Note that shorter the quantity of your order. The higher would be the shipping charge per bag. So don’t fret on seeing the shipment charge of a single sample. The first kilogram carries the highest charge. Shipping charges would lower with bulk orders.

In short, you need to think about shipping expenses and effort involved. Before deciding to manufacture your leather bags overseas.

Sustainability and Compliance

Sustainability and compliance with regulations are often overlooked when importing bags from foreign manufacturers. Many consumers today are more conscious of the impact their purchases have on the environment. And they might be more likely to choose sustainable products.

If your customer base is like that. Then look for suppliers who prioritize sustainable and ethical practices. When sourcing materials for your leather bags. This includes finding suppliers who use eco-friendly and biodegradable materials. Who follow process of production to reduce waste and energy consumption. And those who maintain fair labor practices.

It is better to ensure compliance with local and international regulations. This includes ensuring that the materials used in production are not restricted or prohibited. That the manufacturing process meets environmental and labor regulations. And that the final product is safe for use and meets any required certifications or labeling. By prioritizing sustainability and compliance in your manufacturing process, you can create a product that aligns with the values of your target audience.

However, if you are starting out a new venture. In general, you are unsure of the type of customer base you have. Then cost reduction might get more preference than sustainability itself. In Osfelle we provide our customers with both chrome tanned leather and vegetable tanned leather (eco-friendly) for manufacturing leather bags. Note that eco-friendly leather is more expensive than general tanned leather. Which you chose is up to you to decide what type of brand personality you want to build for your business.

Conclusion

Overseas manufacturing can be a cost-effective solution for producing high-quality leather bags. However, approach this process with caution and consideration for all factors involved. From communication and design to quality control and sustainability. There are many aspects to keep in mind when working with an overseas manufacturer. This article was written not to demotivate you from manufacturing abroad. But to prepare you for what is to come.

As an expert in the industry, We here to support you in your overseas manufacturing requirements. With our knowledge and experience, we can help you navigate through the complexities of this manufacturing process.

Take time to carefully consider all aspects of overseas manufacturing. And chose to work closely with a trusted partner like Osfelle. So that you can create beautiful, high-quality leather bags that meet your specifications. And exceed your customers\’ expectations. Let us help you turn your vision into a reality.

And to manufacture leather bags from Bangladesh just click the WhatsApp button below.

Author

Business Communication Specialist & Leather and Leather Goods Industry Expert

View all posts Khan imtiazkhanbulbul@gmail.com